Machinery and Equipment

- A. Pipe Jacking Sliplining Machine

Pipe Jacking Sliplining Machine

AMR-200 - Sliplining Machine Set

• Pushing Capacity 200 Tons @ 5,000 psi oil pressure

• Power Pack Axial Piston Pressure Compensated Pumps

Primary Pump with 25 GPM flow capacity is rated to 5,000 psi

Auxiliary Pump Unit with 10 GPM flow capacity rated to 3,500 psi

• Stroke 8 feet (hydraulic jacks are mounted vertically)

• Foot Print 16’x11’ (Fits inside 17’ diameter circular shaft)

• Push Ring Custom Made per Project – Not included in the set

Hydraulic Power Pack

Forklift Skid Mounted

Single Point Crane Lift Hook

California emissions Rated but not permitted (by the buyer)

M4045 HF Diesel Engine

Hydraulic Hose Package

120’ overall length

40’ quick connect segmentsPipe Hold Down Mechanism

Two hydraulically activated arms

Control circuits with valves and

pressure gauge on the panel

Arm design is predicated on the

GRP pipe shape and limitations

Upper Jack Assembly

Vertical jacks placed within the

top girder leg housing to

minimize the rig foot print - B. Water Conservation Technology Int.

Water Conservation Technology Int.

Problems

Scaling

WCTI Solutions

The major surface water minerals are Ca, Mg, Na, Cl, SO4, alkalinity and silica. The WCTI process uses a high efficiency water softener, where the sodium is exchanged for Ca/Mg, eliminating the low solubility salts that scale, therefore:

NO SCALINGCorrosion

TEvaporation of water saturates silica, TDS, and alkalinity (pH) which catalyze polymerization of silica to amorphous silicates. This form of silica does not form deposits and is an outstanding corrosion inhibitor, therefore with WCTI:

TEvaporation of water saturates silica, TDS, and alkalinity (pH) which catalyze polymerization of silica to amorphous silicates. This form of silica does not form deposits and is an outstanding corrosion inhibitor, therefore with WCTI:

NO CORROSIONBiological Fouling

The elevated pH and TDS are naturally bio-static to bacteria, spores, and viruses, and denature proteins and enzymes, therefore with WCTI:

The elevated pH and TDS are naturally bio-static to bacteria, spores, and viruses, and denature proteins and enzymes, therefore with WCTI:

NO NEED FOR TOXIC BIOCIDESTower Blowdown

Natural pH/TDS increase as water is evaporated and it concentrates minerals, therefore with WCTI:

Natural pH/TDS increase as water is evaporated and it concentrates minerals, therefore with WCTI:

ZERO TOWER BLOWDOWNProcess Upsets

This process is very tolerant of upsets and it is self correcting (i.e. not affected by water quality and load variations), therefore with WCTI:

This process is very tolerant of upsets and it is self correcting (i.e. not affected by water quality and load variations), therefore with WCTI:

HIGH PROCESS TOLERANCECost of Make-up Water

The WCTI process promotes “zero tower blowdown”, reducing the make-up water rate, therefore:

The WCTI process promotes “zero tower blowdown”, reducing the make-up water rate, therefore:

$ SAVINGS in WATER USAGECost of Blowdown Discharge

The WCTI process eliminates the need for blowdown discharge to sewer and/or processing blowdown through water treatment facilities, therefore:

The WCTI process eliminates the need for blowdown discharge to sewer and/or processing blowdown through water treatment facilities, therefore:

$ SAVINGS in ELIMINATING DISCHARGECost of Water Treatment Chemicals

The WCTI process eliminates the need for blowdown discharge to sewer and/or processing blowdown through water treatment facilities, therefore:

The WCTI process eliminates the need for blowdown discharge to sewer and/or processing blowdown through water treatment facilities, therefore:

$ SAVINGS in ELIMINATING DISCHARGE - C. Odor Control

Odor Control

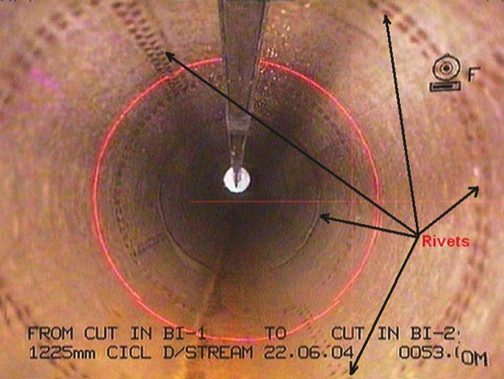

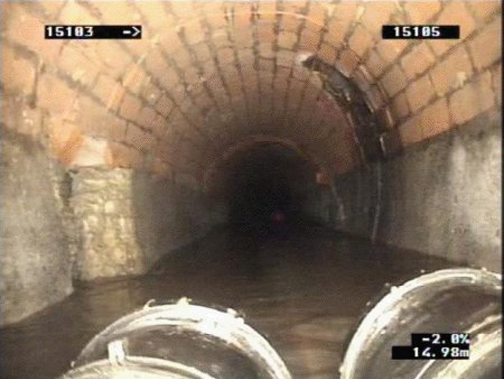

- D. CCTV Equipment

CCTV Equipment

-

- http://www.langpierceclient.com/americore/resources/bg1.jpg